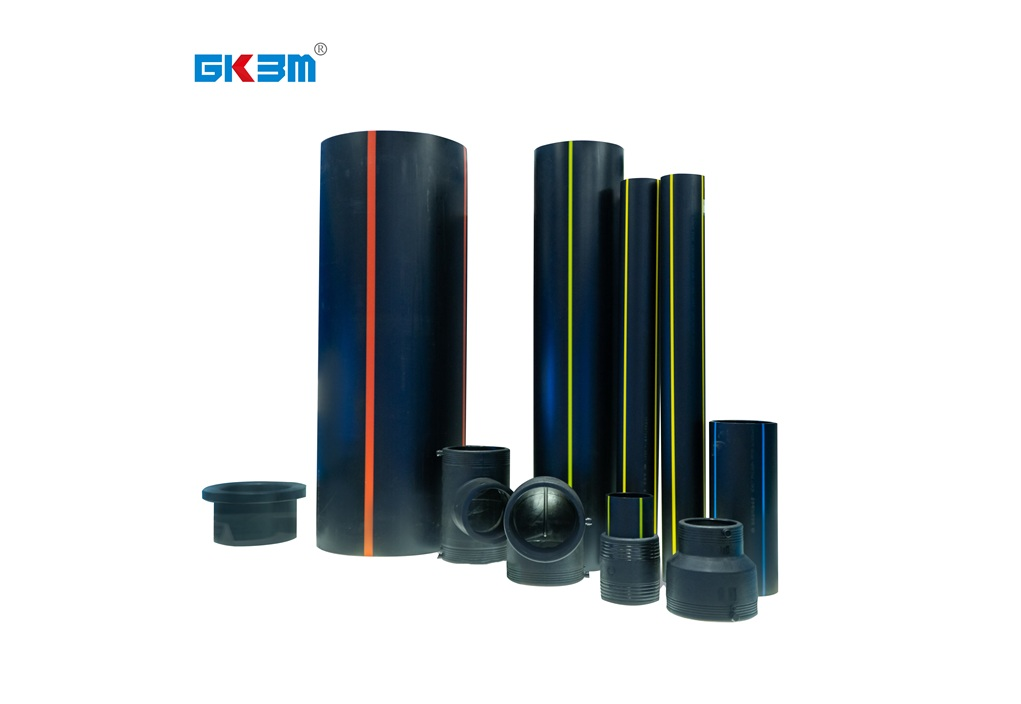

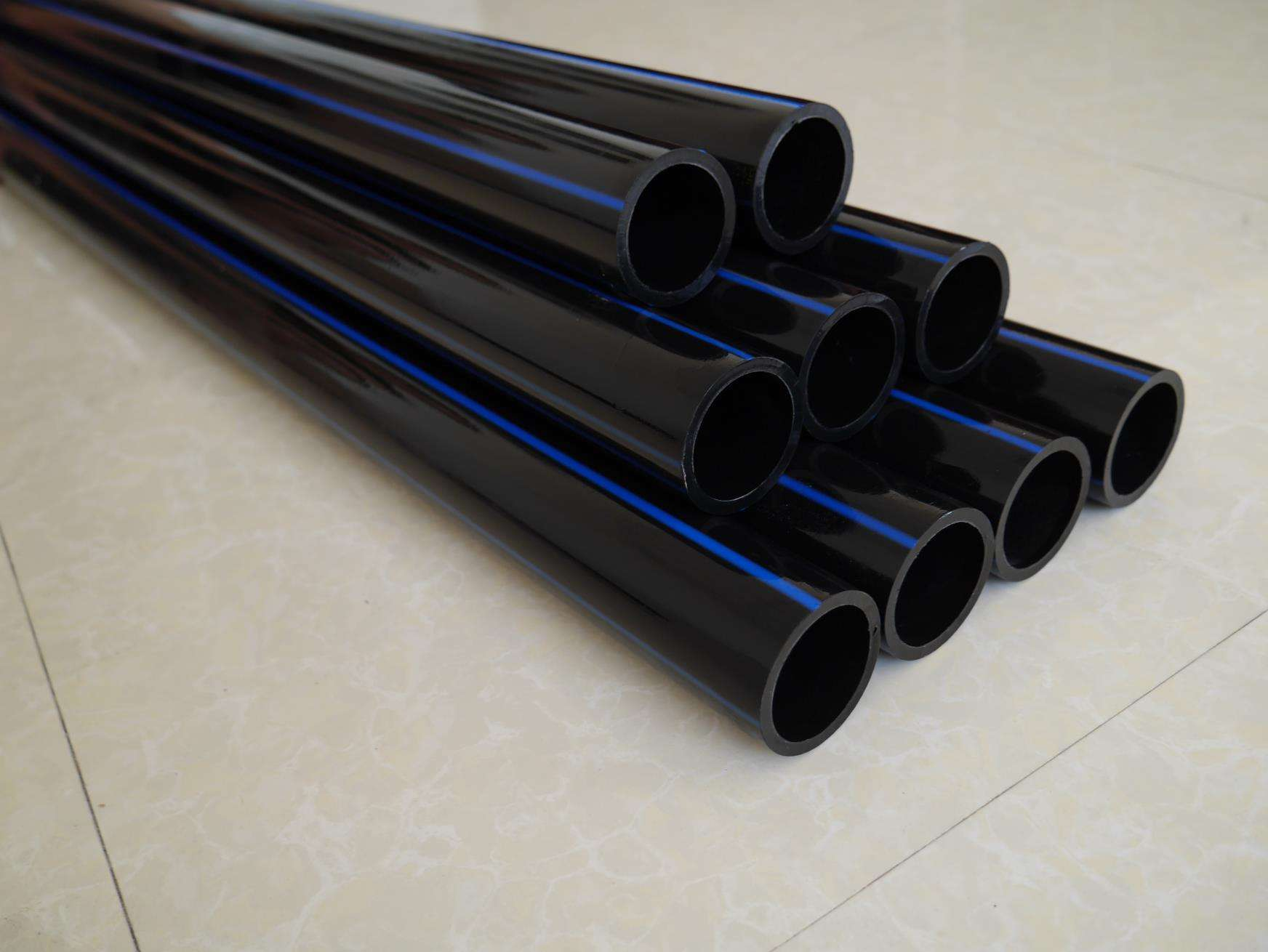

Plastic gas piping is manufactured primarily from synthetic resin with appropriate additives, serving to convey gaseous fuels. Common types include polyethylene (PE) pipes, polypropylene (PP) pipes, polybutylene (PB) pipes, and aluminium-plastic composite pipes, with PE pipes being the most widely utilised.

Performance Advantages

Superior Corrosion Resistance: Plastic materials exhibit stable chemical properties and resist corrosion from most substances. During gas transmission, they remain unaffected by impurities in the gas or soil conditions, significantly extending pipeline lifespan. For instance, in regions with fluctuating soil pH levels where metal pipes are prone to rusting, plastic gas pipelines maintain stable operation.

Flexibility: Lightweight and highly flexible, these pipes can accommodate ground subsidence, displacement, and vibrations to a certain extent. In earthquake-prone zones or areas with unstable geological conditions, plastic gas pipelines reduce the risk of rupture caused by ground movement, ensuring safe gas transmission. For instance, in certain earthquake-frequent cities in Japan, the adoption of plastic gas pipelines has significantly lowered the incidence of gas leaks following seismic events.

Convenient connection with superior sealing: Typically employing heat fusion or electrofusion joining methods, the joints become integral with the pipe material after connection, delivering excellent sealing performance and significantly reducing the possibility of gas leakage. This connection method is relatively simple to operate, offers high construction efficiency, and effectively shortens the construction cycle.

Smooth inner walls for high gas transmission efficiency: The smooth internal surface minimises friction resistance during gas flow, reducing energy loss, enhancing transmission efficiency, and lowering operational costs. Compared to metal pipes of equivalent diameter, plastic pipes demonstrate superior gas-carrying capacity.

Environmentally sustainable: Certain plastic gas pipe materials are recyclable, meeting ecological standards. Furthermore, their production and installation processes generate minimal environmental pollution.

Application Scenarios

Urban Gas Transmission Networks: Plastic gas pipelines are extensively employed in urban gas supply systems, serving both medium-pressure pipelines between gate stations and residential area pressure-regulating stations, and low-pressure pipelines connecting these stations to end-users within residential areas. For instance, newly developed residential areas in major cities like Shanghai and Guangzhou predominantly utilise plastic gas pipelines for gas transmission.

Industrial Gas Distribution: Within factories and enterprises with substantial gas requirements, plastic gas pipelines facilitate internal gas distribution and conveyance. This includes chemical plants and glass manufacturing facilities, where high standards of gas safety and stability are paramount – plastic gas pipelines effectively meet these demands.

For selection of GKBM gas pipelines, please contact info@gkbmgroup.com

Post time: Oct-03-2025