Within contemporary architectural design, stone curtain walls have become the standard choice for the facades of high-end commercial complexes, cultural venues, and landmark buildings, owing to their natural texture, durability, and customisable advantages. This non-load-bearing facade system, featuring natural stone as its core cladding, not only imbues buildings with distinctive artistic character but also achieves dual assurance of aesthetic appeal and structural safety through scientifically engineered internal frameworks. This advances facade technology towards greater efficiency, environmental sustainability, and longevity.

Introduction to Stone Curtain Walls

The core appeal of stone curtain walls stems from the unique properties of natural stone. Panels predominantly utilise materials such as granite and marble, with granite being the mainstream choice due to its low water absorption, strong frost resistance, and tolerance to acid-alkali corrosion. Marble, meanwhile, offers rich textures and colours, catering to the personalised demands of high-end cultural and commercial spaces. Through finishing processes such as polishing, flaming, or bush-hammering, stone panels can achieve diverse effects ranging from refined lustre to rugged textures, fulfilling the design aspirations of various architectural styles. Whether for modern minimalist office buildings or neo-traditional cultural venues, stone curtain walls can forge distinctive architectural identities through material and colour coordination.

Structure of Stone Curtain Walls

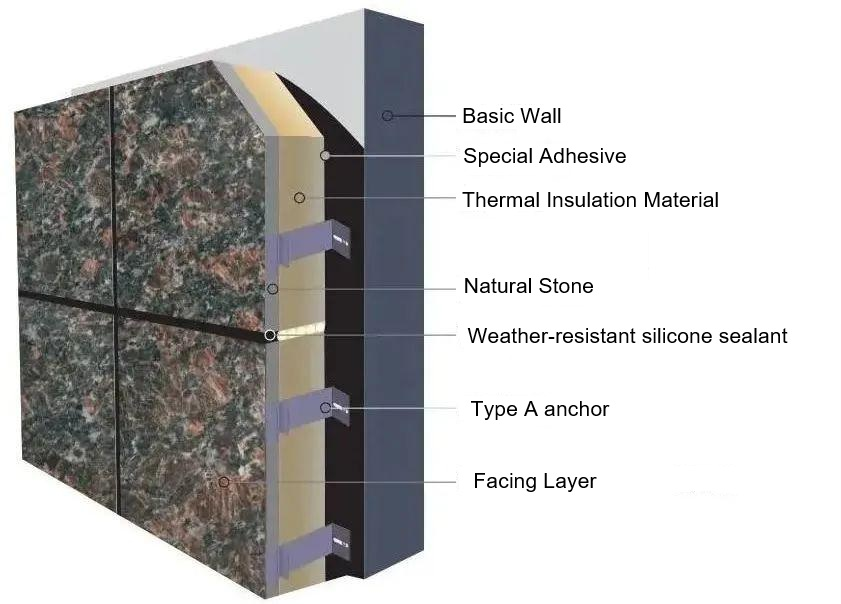

The long-term stability of stone curtain walls relies on the synergistic interaction of four core structural layers: ‘panel-supporting structure-connectors-auxiliary systems’. Each layer fulfils critical functions, collectively forming a reliable system resistant to wind pressure, water ingress, and seismic forces.

1. Panel Layer: The Building’s “Face” and “First Line of Defence”

As the external presentation of the curtain wall, stone panels must satisfy both decorative and structural requirements. Industry-standard panel thicknesses range from 25-30mm, with flame-finished panels requiring an additional 3mm due to surface treatment demands. Individual panel areas are typically limited to under 1.5m² to prevent installation distortion or uneven stress distribution from oversized dimensions. To enhance durability, the reverse side of panels must be coated with silane-based or fluorocarbon protective agents. This prevents rainwater infiltration through stone micro-pores while mitigating efflorescence and colour variation issues—a detail extending stone curtain wall service life to over 20 years.

2. Support Structure: The ‘Skeletal Framework’ and ‘Load-Bearing Core’

The supporting structure serves as the ‘skeleton’ of the stone curtain wall, comprising vertical main frames and horizontal secondary frames that bear the weight of the panels and external loads. Vertical main frames typically utilise channel steel, I-beams, or aluminium alloy profiles, while horizontal secondary frames commonly employ angle steel. Materials should prioritise stainless steel or hot-dip galvanised carbon steel to ensure corrosion resistance. During installation, the main framework is fixed to the building structure via embedded anchors or chemical bolts. Secondary battens are bolted to the main framework, forming a grid-like support system. For curtain walls exceeding 40 metres in height, the main framework spacing is typically controlled between 1.2 and 1.5 metres. Secondary batten spacing is adjusted according to panel dimensions to ensure each stone slab receives stable support.

3. Connectors: The “Bridge” Between Panels and Framework

Connectors serve as the critical interface between stone panels and the supporting structure, requiring both strength and flexibility. Current mainstream connection methods include back-bolted, short-slotted, and T-shaped bracket systems: Back-bolted systems utilise bottom-expansion technology, securing bolts to stone without expansion forces, making them suitable for large-format panels; Short-slot systems feature 1-2 slots cut into opposite edges of the stone, into which stainless steel hangers are inserted for connection. This facilitates straightforward installation and allows for adjustments. All connectors must be fabricated from stainless steel, with neoprene rubber washers positioned at points of contact with the stone. This prevents electrochemical corrosion between metal and stone while absorbing impact from vibrations.

4. Auxiliary Systems: The “Invisible Defence Line” for Waterproofing and Insulation

To withstand climatic impacts, stone curtain walls require comprehensive auxiliary systems: For waterproofing, a 100-150mm air cavity is reserved between the curtain wall and the main structure, lined with a waterproof breathable membrane. Panel joints employ dual sealing with “foam strips + silicone weatherproof sealant”. Drainage channels and holes are installed horizontally every 3-4 layers to ensure prompt rainwater evacuation; For thermal insulation, the air cavity is filled with rock wool or extruded polystyrene boards, seamlessly integrated with the building’s primary insulation layer to achieve energy savings. Taking northern regions as an example, stone curtain walls with insulation can reduce building energy consumption by 15%-20%.

‘Stone curtain walls are not merely a building’s “outer garment”, but a fusion of technology and artistry.’ From landmark structures to public infrastructure projects, stone curtain walls continue to infuse urban skylines with natural texture and technological prowess through their distinctive advantages.

Our Email: info@gkbmgroup.com

Post time: Oct-09-2025