Architectural curtain walls not only shape the unique aesthetics of urban skylines but also fulfil core functions such as daylighting, energy efficiency, and protection. With the innovative development of the construction industry, curtain wall forms and materials have undergone continuous iteration, giving rise to multiple classification methods.

I. Classification by Structural Form

Structural form is the core dimension for classifying architectural curtain walls. Different structures determine the installation method, load-bearing capacity, and applicable scenarios of curtain walls. Currently, they can be broadly categorised into four main types:

Framed Curtain Walls: Traditional and versatile, suitable for small to medium-sized projects

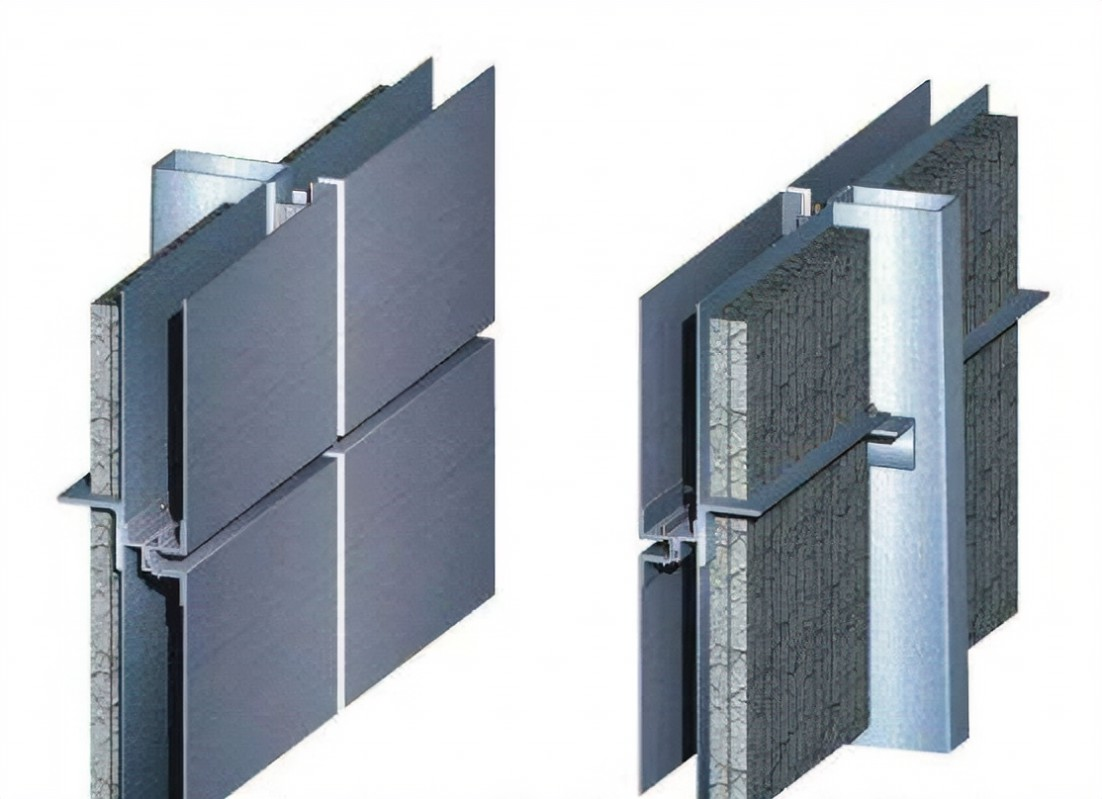

The most fundamental type, comprising aluminium alloy profiles forming a framework (mullions and transoms) to which glass or stone panels are fixed. This category includes both ‘exposed frame’ and ‘concealed frame’ variants. Exposed-frame systems feature visible structural elements, creating a layered visual effect commonly seen in commercial buildings like offices and shopping centres. Concealed-frame systems hide the framework behind the panels, delivering a seamless, transparent appearance that offers unobstructed urban vistas.

Unitised Curtain Wall: Factory-prefabricated for efficient installation in super-tall buildings

Unitised curtain walls divide the façade into multiple ‘unit panels’. Frames, panels, and seals are assembled in the factory before being transported to the site for hoisting and joining. As most processes are standardised in factory production, unitised curtain walls achieve over 30% higher installation efficiency than framed systems. They also offer superior sealing performance, effectively resisting wind and water ingress, making them the preferred choice for super-tall buildings.

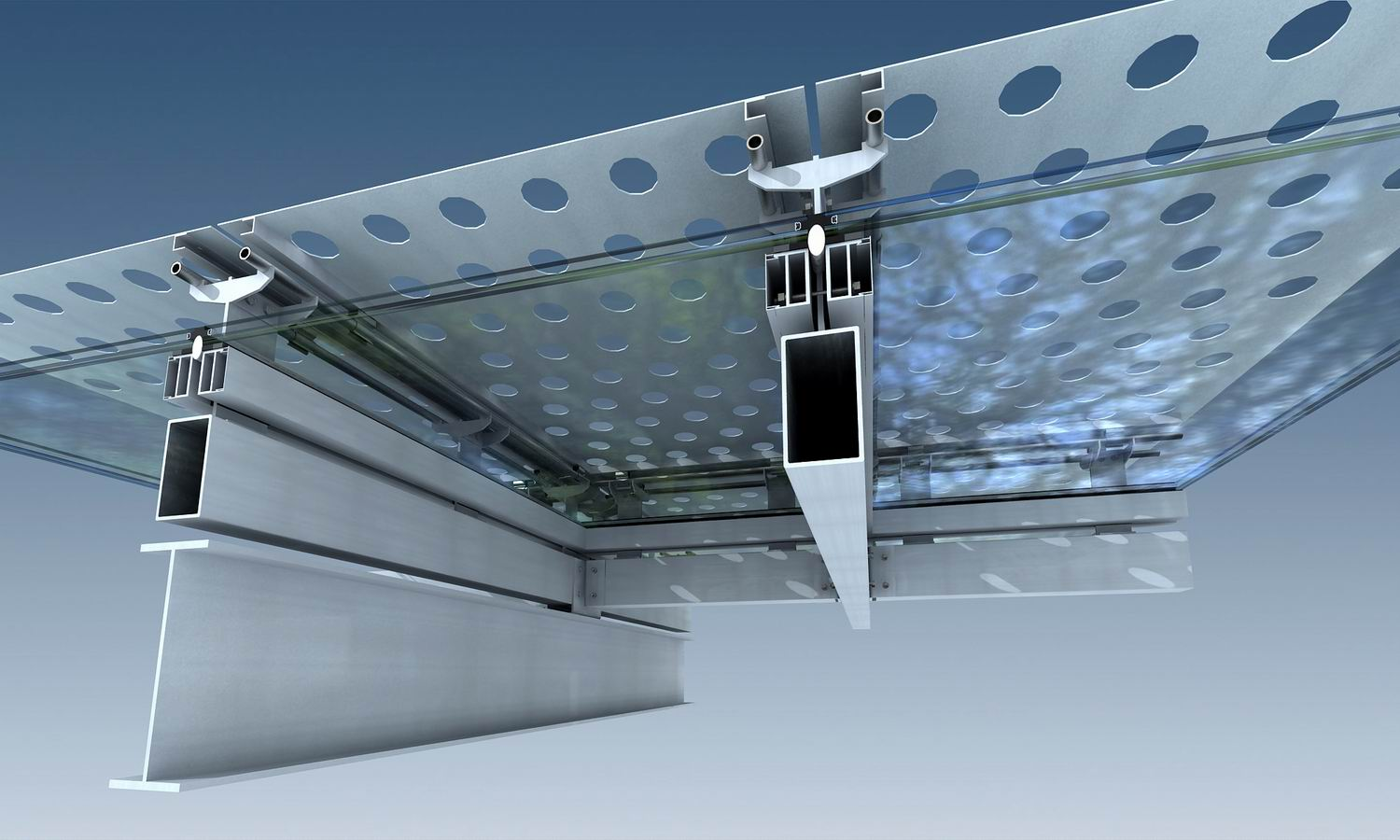

Point-supported curtain walls: Minimalist aesthetics, optimised for expansive spaces

Point-supported curtain walls employ metal connectors to ‘point-fix’ glass panels to steel or concrete supports. The framework is entirely concealed, with panels secured solely by “points” of support, creating a visually ‘floating’ effect that exudes modernity. This system is frequently employed in large-span, expansive structures such as airport terminals and exhibition centres. When combined with curved forms, it fosters open, airy interior spaces.

Prefabricated Curtain Walls: Modular Integration for Green Building

Prefabricated curtain walls represent a recent structural innovation, integrating functional modules for insulation, soundproofing, and fire resistance. These are fully prefabricated in factories, requiring only rapid on-site assembly using bolts and other connectors. Such systems align with the green development trend of ‘prefabricated construction’, reducing wet operations on-site and minimising construction waste. Their high functional integration meets multiple requirements including building energy efficiency and sound insulation. They are now progressively applied in projects such as affordable housing and industrial parks.

II. Classification by Panel Material

Beyond structural form, panel material constitutes another key classification criterion for curtain walls. The properties of different materials determine the appearance, performance, and suitability of the curtain wall for specific applications:

Glass Curtain Walls: The Transparent Mainstream with Rapid Technological Advancement

Glass curtain walls, featuring glass as the core panel, represent the most widely adopted type. They can be further categorised into standard glass curtain walls, insulated glass curtain walls, Low-E glass curtain walls, and photovoltaic glass curtain walls. Among these, Low-E glass curtain walls effectively block infrared radiation, reducing building energy consumption and aligning with green building standards; Photovoltaic glass curtain walls integrate solar power generation with curtain wall functionality. For instance, sections of the Shanghai Tower incorporate photovoltaic modules, achieving dual functions of electricity generation and architectural decoration.

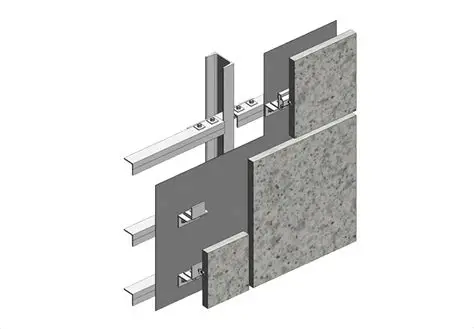

Stone Curtain Walls: Substantial Texture, Suited to Premium Buildings

Stone curtain walls utilise natural stone panels, offering substantial texture and exceptional durability. They convey an elegant and imposing architectural style, frequently employed in high-end projects such as hotels, museums, and government office buildings. However, stone curtain walls possess considerable self-weight, demanding high structural load-bearing capacity. Furthermore, natural stone resources are finite, leading to the emergence of alternative materials in recent years, such as imitation stone aluminium composite panels.

Metal Curtain Walls: Lightweight, Durable, and Flexible in Form

Metal curtain walls utilise panels such as aluminium alloy sheets, aluminium-plastic composite panels, or titanium-zinc sheets. They are lightweight, high-strength, and adaptable to complex shapes, capable of forming curved surfaces, folded lines, and other intricate forms, making them suitable for irregularly shaped buildings. Furthermore, metal curtain walls offer excellent corrosion resistance and low maintenance costs, demonstrating significant advantages in coastal regions and highly polluted environments.

Other novel material curtain walls: functional innovation expanding application boundaries

Technological advancements have spurred the emergence of novel curtain wall materials including terracotta panel systems, glass-fibre reinforced cement (GRC) cladding, and ecological plant-integrated facades. Terracotta panel facades combine the natural texture and eco-friendly properties of clay, making them suitable for cultural tourism and creative industry buildings. Plant facades integrate greenery with the structure, such as the modular plant facade on an ecological office building in Shanghai, achieving ‘vertical greening’ to enhance the building's ecological function and becoming a new highlight in green architecture.

From framed to prefabricated systems, and from glass to photovoltaic materials, the evolution of curtain wall classifications reflects not only technological advancement but also the convergence of architectural aesthetics and functional requirements.

Contact info@gkbmgroup.com for a range of curtain wall system.

Post time: Sep-22-2025