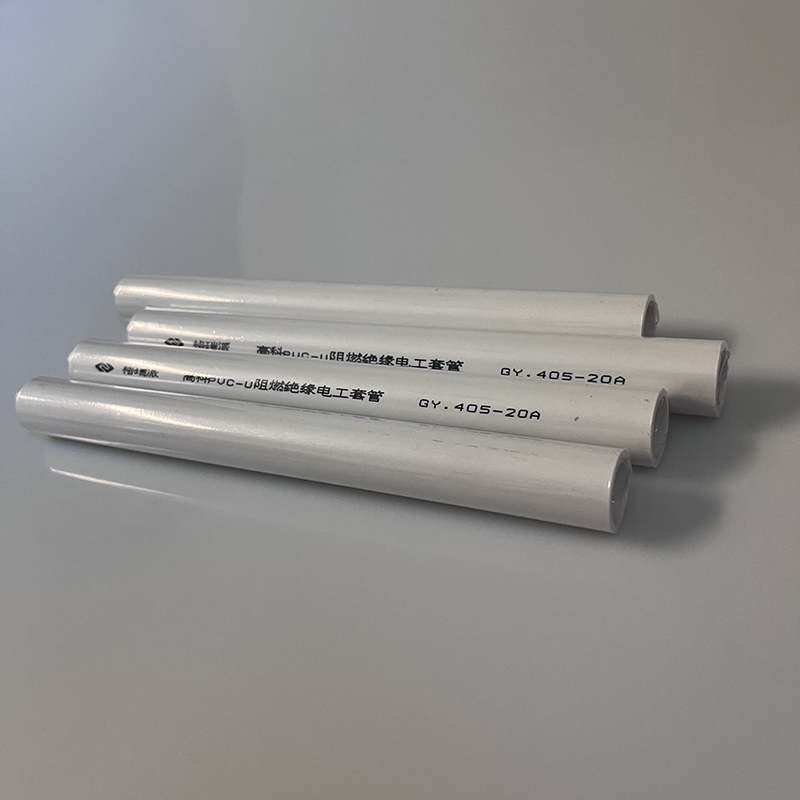

PVC Electrical Protective Pipe

PVC Electrical Pipe’s Features

1.Strong weather resistance, no discoloration during storage: the use of domestic first-class titanium dioxide and no plasticizer formula makes the product have strong weather resistance, no discoloration or brittleness during use and storage.

2.Good toughness and strong impact resistance: the impact resistance is 10% higher than the corresponding insulated electrical pipe on the market.

3.Excellent flame retardancy and insulation: The flame retardant is added to the formula, which improves the flame retardancy of the product by 12%, good resistance to electrical breakdown, and a voltage rating of

1000V.

4. Complete product range: able to meet the usage requirements of construction projects in various seasons in the south and north.

5. Complete supporting pipe fittings: it can meet both the surface installation project and the concealed installation project.

Why Choose Gaoke PVC Electrical Pipe

1. High-quality raw materials: Hi-tech Pipeline uses advanced domestic and foreign high-quality raw materials such as Borealis, Hyosung, PetroChina, and Sinopec, which has laid the source of high-quality products;

2. Advanced production equipment: Gaoke Pipeline is equipped with battenfeld-cincinnati and other domestic and foreign advanced first-class production lines to ensure stable quality in the production process;

3. Professional technical team: Gaoke Pipeline has a strong technical R&D team of various types of mid-level and senior engineers, adhering to the spirit of craftsmanship and striving for excellence to ensure the stable production of products;

4. Complete testing equipment: Gaoke Pipeline is equipped with a national testing center accredited by the National CNAS Laboratory, with complete testing items and reliable testing quality, ensuring that each pipeline is of excellent quality, safe and reliable;

5. Complete product support: Gaoke Pipe has more than hundreds of various extrusion production lines and injection molding production lines/sets, with an annual production capacity of more than 200,000 tons. Its products cover more than 1000 products in ten series and 18 categories in the two major fields of municipal administration and construction. varieties, with one-stop centralized supply capabilities, and is the comprehensive service provider with the most complete supporting facilities in the domestic plastic pipe industry;

6. Improve the service team: Hi-tech Pipeline has a professional logistics service team and a technical service team to ensure quality and quantity and deliver on time. It provides all-round and more professional pre-sales, in-sales and after-sales services for various products, and is committed to "please sit back and enjoy the results." service concept.

© Copyright - 2010-2024 : All Rights Reserved.

Sitemap - AMP MobileWindows & Doors, Sliding Door Window, Sliding Profiles, Upvc Profiles, Window Upvc Door, 105 Upvc Sliding Window Profiles,